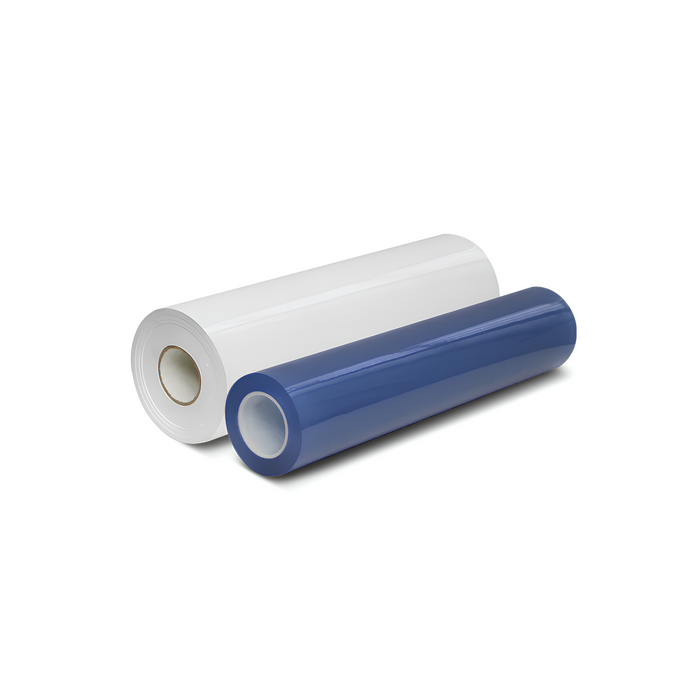

UV DTF Film Roll -A&B - White 23.6" 328'

Features

UV DTF Film Roll – A&B – White 23.6" 328'

UV DTF Film Roll – A&B – White 23.6" 328' is a high-quality printing film designed for Direct-to-Film (DTF) printing applications. This white film provides a solid, opaque base that ensures vibrant colors and consistent print quality, making it ideal for professional and creative projects alike. Its durable PET material resists tearing and curling during the printing and transfer process. With a 23.6-inch width and 328-foot length, it allows for large-scale production runs and minimizes downtime, offering both efficiency and convenience for businesses and hobbyists. This film is compatible with UV DTF printers and supports both soft and rigid surfaces, including textiles, leather, and coated materials.

Features

– Opaque white base ensures vivid color reproduction and sharp detail.

– PET film provides durability, flexibility, and resistance to curling or tearing.

– Wide 23.6" roll and 328-foot length support large projects with fewer roll changes.

– Compatible with a variety of UV DTF printers and adhesive powders.

– High-quality material maintains print integrity during curing and transfer.

How to Use

– Load the A&B Film Roll – White onto your UV DTF printer according to manufacturer instructions.

– Print your desired design directly onto the film using UV inks.

– Allow the printed layer to cure under UV light for full adhesion and durability.

– Apply adhesive powder over the printed side if required by your transfer process.

– Transfer the final design to your target surface using consistent pressure, ensuring full contact.

Benefits

– Creates vibrant, professional-quality prints with strong color opacity.

– Works seamlessly on various surfaces, including fabrics, leather, and coated materials.

– Durable film reduces errors and improves transfer reliability.

– Long roll length supports high-volume production and reduces waste.

– Provides a reliable foundation for consistent, repeatable results across multiple prints.

Film Roll – A&B – White 23.6" 328' is particularly valued for applications where color vibrancy and sharp contrast are essential. Unlike clear or translucent films, the white base enhances pigment coverage, producing richer colors and maintaining detail even on dark fabrics. This makes it ideal for creating custom t-shirts, apparel, promotional merchandise, and decorative items. Designers and print shops benefit from consistent opacity and quality, ensuring that the finished product meets professional standards.

The film’s PET construction also contributes to smooth printing performance. Its flexible yet strong surface allows easy handling during large print runs. It resists curling, folding, or tearing, which can compromise the design or interrupt production. Additionally, this material ensures even ink adhesion and curing, resulting in prints that resist cracking, peeling, and fading over time. This makes it a dependable choice for both small-scale and industrial-scale printing operations.

Its compatibility with UV DTF printers and adhesive powders adds to its versatility. The film supports both A&B film configurations, making it suitable for layered designs or transfers requiring adhesive application. Users can produce durable, high-resolution graphics suitable for textiles, plastics, wood, and other surfaces. The 328-foot length of the roll is particularly useful in busy print shops, as it minimizes downtime from roll changes and supports continuous workflow.

Film Roll – A&B – White also enhances production efficiency. With precise alignment, consistent printing quality, and reduced errors, users can save time and reduce material waste. The opaque white base ensures the colors remain consistent across different batches, providing professional results for large orders. Its high-quality surface ensures smooth transfer during heat pressing, reducing the risk of bubbles or uneven application.

Many users prefer this film for projects requiring bright, bold colors, as it provides a strong foundation for UV inks to stand out. From apparel and custom garments to product packaging and signage, the UV DTF Film Roll – White meets a variety of production needs. Its versatility allows for creative experimentation, supporting detailed designs, gradients, and multi-layered graphics without compromising print integrity.