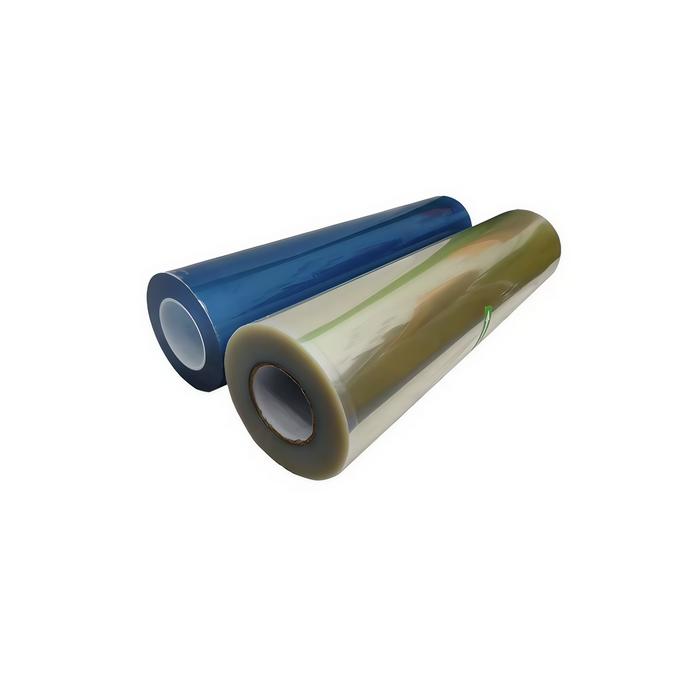

UV DTF A&B Film Roll- Clear 23.6" 328'

Features

The Innovation Behind UV DTF Technology UV DTF Film Roll

The UV DTF A&B Film Roll - Clear is the gold standard for large-format UV transfer production. This high-capacity film set is designed for industrial-grade roll-to-roll UV DTF printers. It enables the creation of premium "sticker" transfers that adhere to virtually any hard surface. With a substantial 100-meter length and a wide 60cm format, this roll is built for maximum productivity. It is the perfect choice for businesses looking to scale their custom branding operations efficiently.

UV DTF printing has changed how we think about product decoration. The process uses two specialized layers: the A Film and the B Film. The A Film acts as the base where the UV ink and varnish are printed. The B Film is the transfer sheet that carries the adhesive to the final object.

The UV DTF A&B Film Roll - Clear ensures these layers bond perfectly. The "Clear" designation means the carrier is transparent. This allows for precise alignment during application. It also ensures that only the printed design remains on the object. The result is a clean, "no-label" look that rivals direct printing.

Keep your production line running smoothly with our

Maximizing Production with 60cm Wide Format

The 23.6-inch (60cm) width is ideal for high-volume manufacturing. This wider format allows you to "gang" many designs together. You can fit multiple large graphics or hundreds of small logos across the width. This layout flexibility reduces material waste significantly.

Using a wider roll also speeds up the production process. A single pass of the print head covers more area than smaller desktop units. For businesses handling bulk orders, this width is a major competitive advantage. The UV DTF A&B Film Roll - Clear turns your printer into a high-output factory.

Superior Clarity and 3D Embossed Effects

Quality is the hallmark of the Clear film series. The UV DTF A&B Film Roll - Clear offers exceptional optical clarity. This is essential for maintaining the vibrancy of CMYK colors. It also allows the white ink layer to stand out with full opacity.

When combined with UV varnish, this film creates a stunning 3D effect. The raised texture adds a premium feel to any product. It mimics the look of high-end industrial embossing. Because the film is clear, it works beautifully on transparent substrates like glassware. The design appears to be part of the glass itself.

Revolutionize your custom branding with our

Industrial Durability and Strong Adhesion

Transfers made with this film set are built for tough environments. The adhesive on the B Film is formulated for maximum tack. It creates a permanent bond with metal, plastic, ceramic, and wood. Once applied, the transfer is resistant to water, oils, and mild chemicals.

The UV DTF A&B Film Roll is also highly scratch-resistant. This makes it suitable for items handled daily, such as phone cases or tools. The UV-cured inks are protected by the film's top layer. They will not fade or peel even when exposed to sunlight for long periods.

Seamless Integration for Roll-to-Roll Systems

This 100-meter roll is designed for uninterrupted operation. Frequent roll changes slow down production and increase labor costs. The Film Roll minimizes these interruptions. It is wound on a sturdy core that fits all standard 60cm UV DTF printers.

The film feeds through the machine with consistent tension. This prevents wrinkling or skewing during the lamination process. Proper tracking is vital for maintaining the alignment between the ink and the B film. This roll ensures a smooth workflow from the first meter to the last.

Cost-Effective Solution for Large Orders

Purchasing film in 100-meter rolls is a smart financial strategy. It lowers the cost per square meter compared to shorter rolls or sheets. These savings are passed directly to your profit margins. For industrial print shops, the Film Roll is the most economical choice.

Reliability also contributes to cost savings. High-quality films reduce the rate of misprints and failed transfers. Every meter of this roll is quality-checked for consistency. You can trust that the adhesive and coating will perform perfectly every time. This reduces waste and keeps your customers happy.

Versatility Across Multiple Industries

The applications for this film are nearly endless. In the electronics industry, it is used for branding laptops and chargers. In the hospitality sector, it decorates glassware and signage. It is even used in the automotive world for interior accents and decals.

The Film Roll handles curved and irregular surfaces with ease. This allows you to brand items that are impossible to fit in a flatbed printer. It provides a versatile solution for companies that offer a wide range of promotional products. One film set can handle all your hard-surface projects.

Easy Application and User Experience

Creating professional transfers does not have to be difficult. This film set is designed for an easy "peel and stick" application. Once laminated, the transfers can be cut into individual pieces. The user simply removes the carrier film and presses the design onto the object.

The "cold peel" nature of the film ensures a clean release. The ink stays on the object, and the carrier comes away without residue. This user-friendly process is great for retail environments. You can provide customers with high-quality decals they can apply themselves.

Reliability and Quality Control

When you use the Film Roll you are using a professional-grade product. It is manufactured under strict cleanroom conditions. This prevents dust and debris from contaminating the adhesive layer. Purity is the key to a bubble-free and smooth transfer.

The films are also tested for shelf-life stability. They will not become brittle or lose their tack over time. This reliability ensures that your stock remains ready for use whenever a big order arrives. It is a dependable asset for any growing printing business.

Conclusion

The Film Roll is a must-have for serious UV DTF operators. Its combination of width, length, and clarity provides an unbeatable production tool. You can create durable, beautiful, and premium transfers for any market.

Invest in a film that supports your business growth. With 100 meters of high-resolution clear film, you can handle the largest projects with ease. Elevate your branding capabilities today with the industry's most reliable UV DTF film set. Experience the difference that professional-grade materials make in your final product.

You are invited to join the DTF Bank world to stay updated on the latest printing techniques and find inspiration for your creative projects. Follow us on