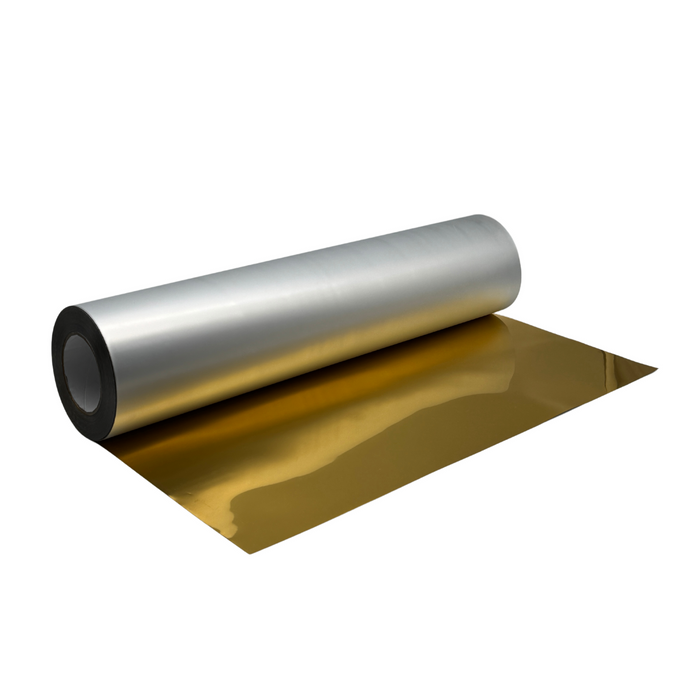

Gold DTF Film - 23.6" x 328'

Features

Gold DTF Film The Future of Metallic Textile Decoration

In the competitive world of custom apparel, standing out requires more than just high-quality prints; it requires offering something your competitors cannot. The Gold DTF Film (23.6" x 328') is a game-changer for professional print shops. This industrial-sized roll (60cm x 100m) allows you to produce stunning, metallic gold designs with the ease of Direct-to-Film technology. No weeding, no screen setup, and no limitations—just pure, liquid-gold brilliance on almost any fabric.

The Evolution of Metallic Printing

Traditionally, achieving a high-quality gold finish on textiles involved complex and labor-intensive processes. Methods like metallic screen printing inks, foil stamping, or heat transfer vinyl (HTV) each came with significant drawbacks. Screen printing requires expensive screen setups and struggles with fine detail. Foil stamping is fragile and can peel easily. Gold HTV requires tedious weeding that makes intricate designs nearly impossible to produce profitably.

Gold DTF Film eliminates all these barriers. It allows you to print complex, high-resolution graphics that feature a true metallic sheen. Because it utilizes the DTF process, you can achieve photographic levels of detail alongside the shimmering luxury of gold, all while maintaining a fast, automated workflow.

Why 23.6" x 328' is the Professional Standard

For businesses operating at an industrial scale, the 60cm x 100m roll format is the gold standard for several reasons:

1. Maximum Production Efficiency

With 328 feet (100 meters) of film at your disposal, you can run large print jobs overnight or through long shifts without the constant need for roll changes. This reduces manual labor and minimizes the risk of alignment errors that occur when starting new rolls.

2. Optimized for Large-Format Printers

The 23.6-inch (60cm) width is the native size for the most popular industrial DTF printers, such as those equipped with dual Epson i3200 or XP600 printheads. This ensures edge-to-edge printing capability and perfect compatibility with automatic powder shaker-dryer units.

3. Lowering Your Unit Cost

Buying in bulk rolls is the most effective way to reduce your cost per square inch. For print shops looking to increase their profit margins while offering a "premium" product line, this 100-meter roll provides the best return on investment.

Technical Superiority: Premium Coating Technology

The secret to a successful metallic transfer lies in the film's coating. Our Gold DTF Film features a multi-layered, double-sided coating designed for the rigorous demands of industrial printing.

Precision Ink Reception

The front-facing side of the film is treated with a high-capacity absorption layer. This layer ensures that CMYK and White ink bond perfectly to the metallic surface without "beading" or running. Even when printing high-density white backing, the film stays stable, preventing ink bleed and ensuring sharp, crisp edges on every design.

Static Control and Tracking

Printing on metallic surfaces can often lead to static buildup, which attracts dust and causes "ink misting." Our film is engineered with anti-static properties on both sides. This ensures smooth feeding through your printer's rollers and prevents the film from sticking to the vacuum bed or the shaker unit.

The Aesthetics of Gold: Liquid Metal on Fabric

The visual impact of Gold DTF cannot be overstated. Unlike "gold-colored" ink, which often looks like a flat mustard yellow, this film provides a genuine metallic reflection.

-

Luxury Branding: Perfect for high-end streetwear, corporate branding, and boutique fashion labels.

-

Holiday & Special Occasions: Ideal for Christmas, anniversaries, and commemorative event apparel.

-

Intricate Details: Because there is no weeding involved, you can print thin lines, small text, and distressed textures that maintain their metallic luster.

Durability and Washability

A common concern with specialty films is their longevity. However, when paired with high-quality DTF Hot Melt Powder, the Gold DTF Film offers exceptional durability. The metallic particles are embedded within the film's structure and protected by the ink and adhesive layers once transferred.

-

Stretchability: The transfer remains flexible and moves with the fabric, preventing the "cracking" often seen with traditional foil.

-

Wash Resistance: When cured correctly (typically at 150-160°C), the gold finish can withstand over 50 wash cycles without significant loss of shine, provided the garment is washed inside out.

Comprehensive Application Guide

To achieve retail-quality results with Gold DTF Film, follow these professional steps:

-

Design Preparation: Prepare your artwork as you would for a standard DTF print. Ensure your design is mirrored before sending it to the RIP software.

-

Printing: Print the color (CMYK) layer first, followed by the white ink layer. The white ink acts as the "glue" and the opacifier that makes the gold stand out on dark fabrics.

-

Powdering: While the white ink is still wet, apply a uniform layer of DTF Hot Melt Powder. Ensure all printed areas are covered.

-

Curing: Pass the film through your dryer or oven at 110°C - 125°C until the powder has completely melted into a "sugar glaze" appearance.

-

Heat Pressing:

-

Temperature: 150°C - 160°C (300°F - 320°F)

-

Pressure: Medium (approx. 4-5 bar)

-

Time: 10 to 15 seconds

-

-

The Peel (Crucial): This is a Cold Peel film. Allow the garment to sit until it is completely cool to the touch before removing the film. Peeling while hot may cause the metallic layer to lift unevenly.

-

Post-Press: For maximum durability and a softer feel, press the garment a second time for 5 seconds using a finishing sheet or parchment paper.

Versatility Across Materials

One of the greatest strengths of Gold DTF Film is its versatility. You are not limited to 100% cotton. This film performs beautifully on:

-

Polyester & Spandex: Ideal for metallic accents on athletic wear.

-

Canvas & Denim: Perfect for custom tote bags and high-fashion jackets.

-

Blends: Works flawlessly on poly-cotton blends without scorching concerns.

Why Your Shop Needs Gold DTF Film Today

The printing market is becoming increasingly saturated. To command higher prices, you must offer unique finishes that customers perceive as high-value. Gold DTF allows you to enter the "Luxury Customization" market with zero additional hardware investment.

By switching to this 100-meter industrial roll, you are choosing a product that balances aesthetics with extreme durability and operational efficiency. Give your customers the 24K look they desire and watch your business grow.

| Feature | Specification |

| Material Type | PET Film with Metallic Gold Coating |

| Roll Width | 23.6 Inches (60 cm) |

| Roll Length | 328 Feet (100 Meters) |

| Peel Method | Cold Peel |

| Compatibility | All Industrial DTF Printers (60cm) |

| Ink Compatibility | Standard DTF CMYK + White Inks |

| Finish | High-Brilliance Metallic Gold |

You are invited to join the DTF Bank world to stay updated on the latest printing techniques and find inspiration for your creative projects. Follow us on Instagram, Facebook, and TikTok to catch professional tips, product reviews, and exclusive deals. You can also subscribe to our YouTube channel for hands-on tutorials. If you are looking for visual ideas for your next project, explore our Pinterest boards, or connect with us on LinkedIn for corporate updates. For any questions or support requests, feel free to reach out to us anytime at info@dtfbank.com.

UV DTF printing technology is transforming production processes by offering unlimited possibilities for personalizing hard surfaces. The

In high-power equipment such as DTF drying ovens and shaker units, managing the electrical flow safely and stably is the heart of the system. The