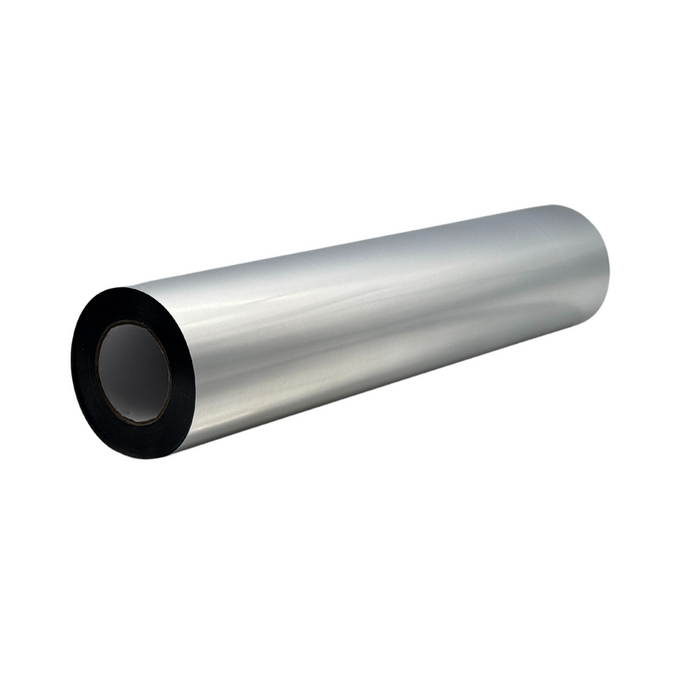

Silver DTF Film - 23.6" x 328'

Features

Silver DTF Film The Professional Standard for Chrome & Metallic Finishes

In the modern world of apparel decoration, offering standard colors is no longer enough to stay ahead. The Silver DTF Film (23.6" x 328') is a specialized industrial product that allows you to break the boundaries of traditional printing. This 100-meter roll provides a stunning, high-shine metallic silver finish that adds an immediate "premium" feel to any garment. Designed for high-volume shops, this film brings the look of liquid chrome and futuristic aesthetics to your production line without the need for additional hardware.

In high-power equipment such as DTF drying ovens and shaker units, managing the electrical flow safely and stably is the heart of the system. The

Redefining Metallic Transfers with DTF Technology

For years, achieving a silver metallic look on clothing was a difficult task. Shops had to rely on metallic screen printing inks, which often felt heavy and cracked over time. Alternatively, they used heat transfer vinyl (HTV), which required tedious weeding and could not handle intricate details.

Silver DTF Film changes the game. By combining the flexibility of Direct-to-Film printing with a high-brilliance metallic base, you can now produce complex, high-resolution silver designs. This film allows for fine lines, distressed textures, and small text that are impossible to achieve with traditional foil or vinyl methods.

UV DTF printing technology is transforming production processes by offering unlimited possibilities for personalizing hard surfaces. The

Why 23.6" x 328' is Essential for Industrial Shops

Efficiency is the foundation of a profitable print shop. The 60cm x 100m roll format is specifically engineered to meet the demands of professional environments.

1. Uninterrupted Production Cycles

With a 328-foot (100-meter) length, your printer can run for hours without manual intervention. This is crucial for shops utilizing automatic shaker-dryer units. Less time spent changing rolls means more time spent fulfilling orders and growing your business.

2. Compatibility with Large-Format Printers

The 23.6-inch width is the native size for the industry’s most popular DTF printers, including those with dual or triple Epson i3200 printheads. It fits perfectly into standard feed systems, ensuring edge-to-edge stability and consistent ink distribution.

3. Maximum Yield and Minimum Waste

Rulo (roll) printing allows for better nesting of designs compared to sheet-fed systems. By optimizing your layout on a 60cm wide canvas, you can significantly reduce film waste, leading to a much lower cost per print.

Technical Excellence: Advanced Multi-Layer Coating

The quality of a metallic transfer depends entirely on how the film interacts with the ink. Our Silver DTF Film features a proprietary coating that ensures a perfect bond every time.

Optimized Ink Reception

The surface is treated to handle high-density ink loads. When your printer deposits CMYK and White ink, the coating holds the droplets in place, preventing "bleeding" or "oiling." This results in sharp, crisp graphics where the silver metallic shine is perfectly contained within the design boundaries.

Anti-Static and Non-Slip Design

Metallic films are often prone to static electricity, which can attract dust and cause the film to stick to the vacuum bed. Our film is double-sided and treated with anti-static agents. This ensures smooth tracking through the printer and prevents the "stepping" errors that can ruin long print runs.

Creating "Colored Chrome" Effects

One of the most exciting features of Silver DTF Film is its versatility. By printing semi-transparent CMYK colors directly onto the silver film, you can create a wide range of metallic shades. For example:

-

Blue Ink on Silver creates a Metallic Blue finish.

-

Red Ink on Silver creates a Metallic Ruby finish.

-

Black Ink on Silver creates a sleek Gunmetal Gray or Carbon finish.

Durability for the Real World

A common misconception is that metallic films are fragile. Our Silver DTF Film is built for durability. When used with professional-grade DTF Hot Melt Powder, the transfer becomes part of the fabric.

-

High Elasticity: The transfer stretches and retracts with the fabric. This prevents the cracking that usually occurs with traditional metallic foils.

-

Wash Fastness: Your designs will maintain their reflective luster even after 50+ wash cycles. To ensure the best results, we always recommend washing garments inside out in cold water.

-

Soft Touch: Despite the metallic base, the final result feels remarkably soft on the skin, avoiding the "plastic shield" feel of thick vinyl.

Step-by-Step Application Guide

To achieve the best chrome-like finish, we recommend following these professional parameters:

-

Preparation: Set your RIP software to mirror the image. Ensure your white ink density is sufficient to create a strong bond with the powder.

-

Printing: Print your design on the matte, silver-coated side of the film.

-

Powdering: Apply DTF Hot Melt Powder while the ink is still wet. Shake off any excess powder—the anti-static coating will help keep non-printed areas clean.

-

Curing: Melt the powder at 110°C - 125°C (230°F - 257°F). The powder should look like a melted, orange-peel texture.

-

Heat Pressing:

-

Temperature: 150°C - 160°C (300°F - 320°F).

-

Time: 10 to 15 seconds.

-

Pressure: Medium to Firm.

-

-

The Cold Peel: This is a Cold Peel product. You must wait for the garment to cool completely to the touch before removing the film. This ensures the metallic particles have fully set into the adhesive.

Broad Market Appeal

Silver DTF Film opens doors to various lucrative markets that standard CMYK printing cannot reach:

-

Athletic & Sportswear: Ideal for "platinum" level jersey numbers and reflective team logos.

-

Tech & Automotive Branding: Perfect for creating decals for laptops, bags, or apparel related to the automotive industry.

-

Streetwear & High Fashion: Metallic silver is a staple in modern streetwear, providing a "high-tech" look that appeals to younger demographics.

-

Special Events: Great for commemorative shirts, anniversaries, and limited-edition merchandise.

Safety and Sustainability

Our Silver DTF Film is manufactured with PET materials that are stable under high temperatures. The coating process is designed to be eco-friendly, and the film does not release toxic fumes during the curing or pressing stages. It is safe for use on children’s apparel and meets international textile safety standards.

Conclusion: Transform Your Business

The Silver DTF Film - 23.6" x 328' is not just a consumable; it is a strategic investment in your shop’s creative capabilities. By offering industrial-strength metallic silver transfers, you can attract higher-paying clients and differentiate your brand in a crowded market.

From the liquid-chrome finish to the effortless "No Weeding" application, this film is designed to make your production faster, easier, and more profitable. Bring the future of metallic printing to your shop today.

| Feature | Specification |

| Film Base | High-Grade PET |

| Finish Type | Metallic Silver / Chrome |

| Roll Width | 23.6 Inches (60 cm) |

| Roll Length | 328 Feet (100 Meters) |

| Peel Method | Cold Peel |

| Anti-Static | Yes, Double-Sided Treatment |

| Washability | Industrial Grade (50+ Washes) |

You are invited to join the DTF Bank world to stay updated on the latest printing techniques and find inspiration for your creative projects. Follow us on Instagram, Facebook, and TikTok to catch professional tips, product reviews, and exclusive deals. You can also subscribe to our YouTube channel for hands-on tutorials. If you are looking for visual ideas for your next project, explore our Pinterest boards, or connect with us on LinkedIn for corporate updates. For any questions or support requests, feel free to reach out to us anytime at info@dtfbank.com.